Clamping System

The clamping hoods ensure absolute stability during the entire test cycle. It is possible to perform measurements in complete safety even on particularly unstable samples, ensuring absolute stability during the hardness measurement. The clamping system allows the measurement point to be precisely visualized, ensuring that each operation is performed correctly and without risks for the operator or the sample.

Testing Area

We have studied the shape of ATI RS with the aim to improve the testing experience. We have designed an innovative work area, with a maximum test height of up to 290 mm and a depth of 210 mm.We have also designed a work area lighting that guarantees the maximum visibility also of the most difficult measurement points, thus facilitating the operator and reducing the probability of measurement errors or breakage of the penetrators, helping to extend their life. The lighting is rechargeable directly on board the machine via a USB port.

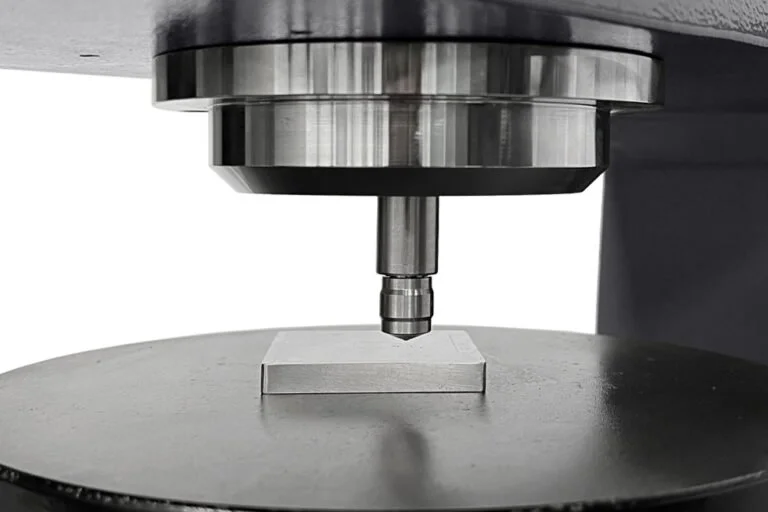

Automatic Hardness Measurement

One button measurement: simply press the START button to get start the entire hardness test cycle. The motorized lifting screw will bring the sample to the testing area. Each phase of the hardness measurement is automatic: contact with the sample, preload, load and measurement occur automatically. During the process, the operator can monitor in real time on the screen each single phase of the test cycle. At the end of the measurement, the result is provided automatically.

Control Panel

The control panel is mounted on the side and connected to a flexible articulated arm, allowing it to be repositioned forward or backward according to the operator’s needs during use. This flexible setup provides excellent adaptability, enabling users to adjust the screen’s position for optimal visibility and easier interaction with the device. Moreover, shifting the panel out of the way creates additional workspace, making it easier to handle larger components and enhancing operational efficiency.

Software

The advanced hardness testing system features a comprehensive and intuitive interface divided into five sections: Setting, Testing, Display, Diagram, and Programming. It supports various international standards (ASTM E140, DIN18625, GB/T) and hardness scales (HRA, HRB, HRC, etc.), allowing users to customize their testing needs.

To ensure accuracy, the system allows for the adjustment of dwelling time from 0 to 60 seconds and can test curved surfaces, correcting results based on the curvature radius. Users can set standard values and deviation limits to facilitate quick assessment of product pass/fail status. The testing process is automated: simply rotate the handwheel to initiate the test, with visual and audible confirmations. Once the dwelling time is reached, the main force is automatically released, allowing for accurate final measurement.