DiaUltra 2-in-1 Diamond Suspension

DiaUltra provides the highest removal, shortest preparation times and best surface quality combined with easy dosing that ensures reproducibility.

DiaUltra is a permanently stable, ready mix of suspension and lubricant.

Based on the newest development in diamond suspensions, DiaUltra has the highest removal rates of any currently available 2-in-1 suspension on the market. With DiaUltra it is possible to reduce the preparation time with up to 40%. At the same time, the surface finish is extremely smooth allowing for further reduction of the following step.

The unique formulation allows to use DiaUltra on all fine grinding discs and polishing cloths with equally good results.

DiaUltra is available with monocrystalline (multicrystalline) diamonds as DiaUltra and with polycrystalline diamonds as DiaUltra Poly.

When Diamond Suspension was developed, precise automatic dosing was made possible by using peristaltic pumps and reproducible preparation methods with well-defined dosing levels were a reality. However, as from the beginning, diamond and lubricant were still applied individually.

The next logical step was to combine suspension and lubricant into one liquid, the 2-in-1 Diamond Suspension. These 2-in-1 suspensions guarantee the correct suspension/lubricant ratio at all times and combine the best possible preparation results with utmost ease of use.

In between the development of the different suspensions the Diamond Stick was introduced as a substitute of the diamond paste. The diamond stick is easier to use than diamond paste, and is, because of the very high diamond concentration, recommended for priming new, unused polishing cloth. It can, contrary to Diamond Paste, also be added during preparation.

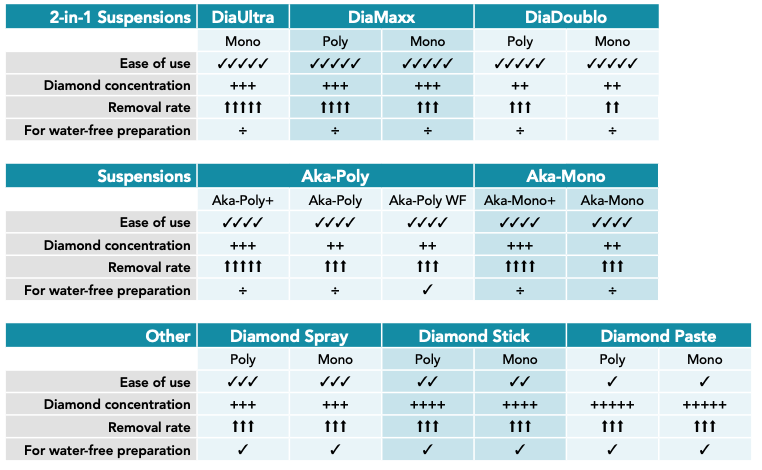

To cater for all the different requests and to satisfy our customers’ wishes, we have developed the widest selection of high quality diamond products.

Most of our diamond products are available in two different versions, with either polycrystalline or monocrystalline diamonds.

The first diamonds to be used for metallographic polishing were natural, monocrystalline diamonds, as used in the production of jewellery. Since then the demand for diamonds for polishing applications has increased dramatically and diamonds are now produced artificially.

Artificial monocrystalline diamonds have replaced natural diamonds in most metallographic applications because they have the same properties. For the highest requirements and the best preparation results, polycrystalline diamonds are used.

Polycrystalline diamonds break down over time, continuously producing small abrasive edges that provide high material removal while producing only shallow scratches. Monocrystalline diamonds will get more and more round over time, losing their cutting ability.

Diamond concentration of 20 ct/l

100% monocrystalline diamonds

Median (50%) 15 µm.

Tolerance 14.2 – 15.8 µm

Upper limit (99%) 21.5 µm

Keep out of direct sunlight.